Ultra-connected, the Industry of the Future project is transforming the industry. The smart industry announce a soft transition, paving the way for an evolution by innovation.

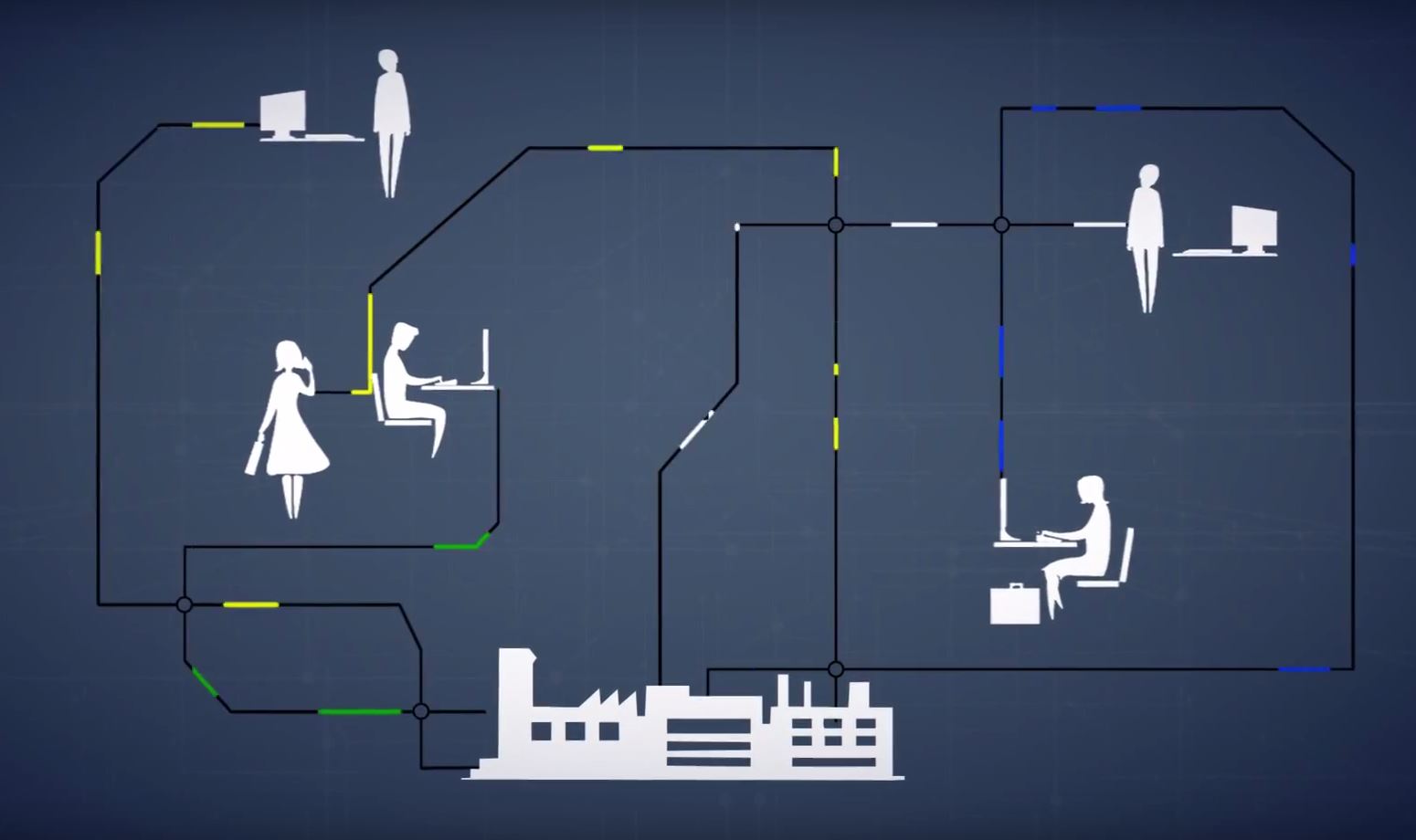

From mechanisation to automation with mass production somewhere along the way, the industrial sector has continued to evolve. With Industry of the Future, considered by some as the fourth Industrial Revolution, digital technology and the Internet have become indispensable in today’s connected production plant. Tools, products and workstations constantly interact and exchange data via the Internet and virtual networks. In order to optimise production plant operation, this smart industry focuses on interconnection.

What change does Industry of the Future herald?

Industry of the Future has arisen out of the combination of several factors: changing technology applied to the industrial sector together with changing customer demands and manufacturing processes. It is responding to four major challenges: to make industry more human, more intelligent, more responsible and finally more efficient.

This is resulting, for example, in:

- optimised and flexible production to adapt to demand in real time

- product quality and traceability, in particular with MES

- improved maintainability using predictive maintenance to maximise the service lifespan of parts

- energy efficiency to reduce the ecological footprint of plants while making them more economical to run and less dependent on energy

- a greater emphasis on people, well-being and safety with, for example, robots and cobots , which are taking over the most difficult tasks from workers and shifting them towards higher value-added operations.

Smart industry: why a gradual transition?

The main tools and technology needed for this transformation already exist. They include augmented reality and virtual reality, big data, the Internet of objects and cloud computing. With Industry of the Future, production processes are being totally reorganised using these existing tools together with far greater emphasis being placed on interconnection. The aim is to progress current products and services, such as, energy efficiency or maintenance , taking into account the interconnections around Industry of the Future.

More than an evolution, Industry of the Future therefore appears rather to resemble a gradual transition in which support is the overriding aspect aimed at maximising industrial performance. Actemium has assisted numerous industrial customers with their transition towards Industry of the Future with, one example being, the introduction of collaborative robots or cobots, whether for assistance with packaging at the Valeo plant in Amiens (France), or jet engine compressor fan manufacturing in Snecma Gennevilliers factory (France). Another example includes the installation of a decision-aid system for managing the Val-de-Marne (France) wastewater network, or even the creation of virtual digital models such as those for the A319/A320/A321 assembly shop at the Airbus Hamburg plant (Germany) to simulate the shop’s operation process prior to its construction.

Innovation driving Industry of the Future

The shift towards connected plants also involves the use of what is now considered mature technology along with new innovative processes: augmented and virtual reality , 3D modelling and simulation, additive manufacturing, 3D printing and even decision-aid tools which all contribute to developing new solutions. “Augmented reality could radically change diagnostic and support services by enabling less qualified operators to shoulder new responsibilities reliably and efficiently”, explains Frank Berger, Business Unit Manager Actemium Smart Industry and Infrastructure Solutions. “Innovation is a crucial lever for differentiating the products and services we provide. Combine with our expertise, It enables us to deliver ever increasing value added to our customers”, adds Sylvain Reumeau, Manager Innovation at Actemium France.

Augmented reality could radically change diagnostic and support services by enabling less qualified operators to shoulder new responsibilities reliably and efficiently.

Actemium also forms partnerships to work on pilot projects, such as the use of augmented reality in order to evolve maintenance and virtual reality for training (see the video below). “At the end of the day, all this new technology could trigger a revolution”, concludes Frank Berger. A main evolution in which Actemium is playing a central role in developing innovation applied to smart industry.